| | | Opening ThemeEnding Theme Recent News North American Anime & Manga Releases For December Here are the North American anime, manga, and light novel releases* for December. Week 1: December 6 - 12 Anime Releases Gekkan Shoujo Nozaki-kun (Monthly Girls'... read more Dec 13, 2022 3:17 PM by Aiimee | Discuss (1 comment)  PV Collection June 21 - 27 Here is a collection of promotional videos (PV), television ads (CM), and trailers for the last week. This thread excludes videos that have already been featured in ... read more Jun 27, 2021 3:04 PM by Snow | Discuss (1 comment) Recent Forum Discussion | |

- Aug 4 | 13 replies | by

Aug 16, 12:01 PM | | | Poll: ... )

- Jul 2, 2021 | 351 replies | by

Aug 8, 3:58 PM | | | Poll: )

- Aug 13, 2021 | 127 replies | by

Aug 3, 6:05 AM | | |

- Jun 4 | 2 replies | by

Jun 4, 7:38 PM | | | Poll: )

- Jul 16, 2021 | 242 replies | by

Apr 6, 4:48 PM |

More Top Anime- 1 Sousou no Frieren

- 2 Fullmetal Alchemist: Brotherhood

- 3 Steins;Gate

- 5 Shingeki no Kyojin Season 3 Part 2

More Top Airing Anime- 1 Monogatari Series: Off & Monster Season

- 2 One Piece

- 3 "Oshi no Ko" 2nd Season

- 4 Doupo Cangqiong: Nian Fan

- 5 Make Heroine ga Oosugiru!

More Most Popular Characters- 1 Lamperouge, Lelouch

- 3 Monkey D., Luffy

- 4 Lawliet, L

- 5 Roronoa, Zoro

Open Access is an initiative that aims to make scientific research freely available to all. To date our community has made over 100 million downloads. It’s based on principles of collaboration, unobstructed discovery, and, most importantly, scientific progression. As PhD students, we found it difficult to access the research we needed, so we decided to create a new Open Access publisher that levels the playing field for scientists across the world. How? By making research easy to access, and puts the academic needs of the researchers before the business interests of publishers. We are a community of more than 103,000 authors and editors from 3,291 institutions spanning 160 countries, including Nobel Prize winners and some of the world’s most-cited researchers. Publishing on IntechOpen allows authors to earn citations and find new collaborators, meaning more people see your work not only from your own field of study, but from other related fields too. Brief introduction to this section that descibes Open Access especially from an IntechOpen perspective Want to get in touch? Contact our London head office or media team here Our team is growing all the time, so we’re always on the lookout for smart people who want to help us reshape the world of scientific publishing. Home > Books > Solvents - Dilute, Dissolve, and Disperse - Insights on Green Solvents and Distillation Evaluation of the Best Operating Conditions in Distillation Columns: A Case Study for the Separation between Nonylphenol and DinonylphenolSubmitted: 13 October 2023 Reviewed: 13 October 2023 Published: 01 February 2024 DOI: 10.5772/intechopen.1003801 Cite this chapter There are two ways to cite this chapter: From the Edited Volume Solvents - Dilute, Dissolve, and Disperse - Insights on Green Solvents and DistillationRaffaello Papadakis and Vilmar Steffen To purchase hard copies of this book, please contact the representative in India: CBS Publishers & Distributors Pvt. Ltd. www.cbspd.com | [email protected] Chapter metrics overview 39 Chapter Downloads Impact of this chapter Total Chapter Downloads on intechopen.com  Total Chapter Views on intechopen.com Nonylphenol is a very important product for the chemical industry due to its widespread use as a base for several other chemical products. Among the major industrial sectors that use nonylphenol is the production of non-ionic surfactants, which are used from the home and personal care industry to the agrochemical industry. This study aims to define the optimal or quasi-optimal operating conditions for the separation system, which is composed of packed columns. Using simulation tools, the best operating conditions are attained, and the dinonylphenol subproduct generation is minimized. The commercial simulator Aspen Plus ® was used for this study as the analysis tool for the mentioned objectives. The developed model is validated with technical data, measures are taken in a nonylphenol plant, and parameters are used in the same plant. From the obtained data from the plant, the best process performance is evaluated regarding cost-benefit analysis and safety concerns. The study shows a potential to reduce the subproduct production by 30% and the reboilers’ heat loads by 2%. - process simulation

- Aspen Plus ® software

- nonylphenol

- distillation column

- packed column

Author InformationJulio cesar ribeiro nunes. - Department of Chemical Engineering, Federal University of São Paulo (UNIFESP), Diadema, SP, Brazil

Ricardo de Freitas Fernandes PontesFabio rodolfo miguel batista. - Department of Chemical Engineering (DEQUI-EEL), Lorena Engineering School, University of Sao Paulo (USP), Lorena, SP, Brazil

Rafael M. Matricarde Falleiro **Address all correspondence to: [email protected] 1. IntroductionNonylphenol is a very important reactant in the surfactant industry, and its main application is in ethoxylated non-ionic surfactants, which use about 80% of the produced nonylphenol [ 1 ]. Nonylphenol is produced by a reaction between phenol, nonene, and a basic catalyst. The various nonylphenol applications range from the home and personal care industry to the agrochemical industry. In chemical terms, nonylphenol is an alkylphenol, hence a phenol derivative where one more hydrogen atom in the aromatic ring is replaced by alkyl radicals. The most important alkylphenols are composed of alkyl radicals that have 2–12 carbon atoms. Besides their use as non-ionic surfactants, alkylphenols are also used as phenolic resins, polymeric additives, and agrochemicals. Nonylphenol is produced from an alkene (nonene) by acid catalysis (Lewis acid or ion-exchange resin), ensuring the replacement of hydrogen by the alkyl radical in the aromatic ring [ 1 , 2 ]. The overall reaction is highly exothermic (−23.7 kcal/gmol) and reversible as presented in Figure 1 .  Nonylphenol synthesis overall reaction. The overall reaction process synthesizes the isomers ortho-nonylphenol and para-nonylphenol, and the latter is the major product. Besides the main product, the process also produces dinonylphenol as a subproduct, and this occurs by the reaction between one nonylphenol molecule with one nonene molecule. Dinonylphenol is much less used in the chemical industry compared to nonylphenol. Hence, an optimal operating point must be defined to reduce the dinonylphenol production to the minimum possible value because if this subproduct is produced in relatively large quantities, then the plant profit is reduced. A productive process understanding is required to achieve nonylphenol synthesis optimization. Such understanding is done by theoretical studies that allow technical analysis and plant operation planning. Simulation software is used to evaluate the process under several different conditions without interfering in the plant operation. Moreover, by using simulation software, the optimization studies can be better directed saving time and resources that would be spent if the studies were directed toward a non-optimal configuration. 1.1 Nonylphenol production processFigure 2 presents the nonylphenol productive process used by a major chemical plant in southeastern Brazil. This particular process consists of the following three major unit operations: reaction, phenol recovery, and nonylphenol purification.  Process flowchart for the nonylphenol production process. The phenol alkylation reaction occurs in two serial mixture atmospheric reactors and is filled with an acid ionic exchange resin bed. Reactor 1 (R-1) operates within an 80–130°C range, and Reactor 2 (R-2) operates within an 85–135°C range. The temperature increase is gradual and based on the accumulated production of 1°C for each 300 ton of produced nonylphenol [ 3 ]. The reaction feed stream contains a phenol excess. The major raw material cost comes from the nonene purchase; hence nonene is the limiting reactant. The feed stream contains trace amounts of water from the phenol and nonane. The overall formation selectivity is 96.3% nonylphenol, 2.7% dinonylphenol, and 1% heavier compounds [ 2 ]. The process is catalyzed by an acid ionic exchange resin that replaces a Lewis acid. The use of the resin catalyst reduces the raw material demand, yields less subproduct production, and allows better control of mixing parameters. On the other hand, using resin catalyst requires increased capital costs, and the catalyst activity decreases with time. Therefore, reaction control must account for the activity reduction to ensure efficient reactors’ operation. 1.2 Phenol recoveryAs the name suggests, this stage aims for the recovery of the unreacted phenol. Distillation is the used separation method. A column (D-1) with structured packing (SULZER BX 50) separates phenol from the heavier compounds in the Reactor 2 (R-2) effluent. The column operating pressure ranges from 0.240 to 0.267 bar. The estimated maximum pressure drop from the bottom to the top is about 0.027 bar. Column D-1 temperature profile lies within the 135°C (top) to 256°C (bottom) range. Column D-1 feed stream is composed of nonylphenol, dinonylphenol, phenol, nonene, nonane, and traces of water. Since nonane lowers the nonylphenol yield in the reaction process, Column D-1 operates with a partial condenser to separate nonane from the unreacted phenol. The vapor distillate stream is mostly composed of nonane, nonene, and water, while the liquid distillate stream is phenol-rich. The vapor distillate stream is condensed in the Nonane Condenser (E-2), and the outgoing condensed stream goes to storage. The liquid distillate stream is recycled to Tank TK-4 at the beginning of the process, so the recovered phenol is reused in the reaction. Column D-1 bottom stream is composed of heavier compounds, mainly nonylphenol, and dinonylphenol. As the bottom stream does not meet commercial purity requirements for nonylphenol product, the bottom stream goes to Column D-2 to separate nonylphenol from dinonylphenol. 1.3 Nonylphenol purificationThe final stage aims, as previously mentioned, the attainment of nonylphenol products complying with market specifications (minimum 95% purity). The purification is done in Column D-2, which uses structured packing (SULZER BX 50). This column operates at a high vacuum (0.067–0.073 bar). Therefore, the pressure drop in the column must be limited to a maximum of 0.007 bar. Column D-2 operating temperature range is from 216°C (top) to 277°C (bottom). Nonylphenol at market specification is produced at Column D-2 distillate stream. The purified nonylphenol is then cooled in Exchanger E-6 and stored in Tank TK-7. Therefore, the bottom stream is mainly composed of dinonylphenol, which is also cooled (Exchanger E-7) and stored (Tank TK-8). 2. Packed column and process simulationIn the 1950s, chemical industries used more frequently packed columns as distillation equipment [ 4 ]. Usually, packed columns are used for the separation of mixtures with high relative volatility difference, hence mixtures that are relatively easy to separate [ 5 ]. Packed column interiors are basically completely filled with a packing, which is either packed or random. Unlike a plate column, there is no space between stages, and the only empty spaces in the column are at the top, the bottom, and around the feed stream inlet(s). Random packing is made up of small components such as Rasching and pall rings. These components have defined dimensions and geometric shapes. The column interior is filled with packing but in a random manner. Hence, the packing distribution varies randomly with the column height. While random packing does not have a definite design, structured packing is designed to be the same throughout the stage height. Structured packing is usually formed by perforated metallic sheets that have corrugated sections, in order to create multiple parallel channels in the packing. The structured packing design forces the liquid and vapor streams to flow in countercurrent through the channels forming a liquid film in the packing surface. In this manner, contact between the liquid and vapor is maximized in the structured packing [ 6 ]. The main downside of structured packing is the need for a high feed stream flow rate, otherwise, the liquid film formation throughout the column transversal area is compromised. Consequently, low feed stream flow rates can reduce the interphase contact in the column resulting in low-efficiency stages [ 7 ]. Compared to structured packing, random packing has a lower capital cost and is installed more easily. However, structured packing is more efficient regarding distillation and imposes a lower head loss. Moreover, depending on the random packing component distribution, a preferential path can be formed, short-circuiting the column, and drastically reducing column efficiency [ 8 , 9 ]. In packed columns, other internals are essential to avoid a non-uniform distribution, a preferential path formation, or even liquid flowing through the column’s internal wall. Among these internals, the main ones are the distributors and re-distributors [ 8 ]. Considering the nonylphenol production process, packed columns are fundamental for safe and large-scale production as shown in Figure 1 . However, as many thorough locus studies, process optimization finds problems due to plant operation requirements. To perform any study test, plant production can be seriously reduced or even halted, yielding a profit loss. Additionally, relatively drastic alterations in process conditions can compromise the ability of the plant to return to its original operating conditions. Consequently, process simulators can provide tools to investigate different operating conditions, and these simulators are nowadays widely used in chemical industries. Many process simulators are only able to evaluate a process under a steady state. However, some process simulators can predict the system behavior in a transient state, and this means that the simulator can predict the system behavior when a perturbation occurs. For plants that have different operating regimes, meaning that the process must migrate from one steady state condition to a different one, some transient state process simulators can perform real-time optimization. Such resources enable simulated studies a greater versatility, and a more rigorous evaluation and closer to the system’s actual response. This is crucial for the financial assessment of the productive process [ 10 ]. However, the results attained by a process simulator are only as good as the process model built by the engineers responsible for the process simulation. Therefore, the simulation engineers must have a thorough technical knowledge of the process. This means selecting an accurate thermodynamic model must be selected, the adequate unit operations involved in the process, and also arranging these unit operations to create a coherent productive process. Simulation engineers must also correctly interpret the simulation results, in order to ensure that the simulated model predicts the actual operation with precision. Nowadays, several chemical process simulators are commercially available or even available for free. Aspen Plus® software from Aspen Tech is one of the main available process simulators. This software has an extensive data bank that includes component parameters and unit operations. Hence, this data bank allows Aspen Plus® to achieve accurate simulation results for many processes, specifically for distillation. 3. Case study: nonylphenol separation and purificationThe case study focuses on the nonylphenol-production separation system. Therefore, the study encompasses both the phenol recovery-packed column (D-1) and the nonylphenol purification-packed column (D-2). The system was simulated using Aspen Plus® and is shown in Figure 2 . For the study development, technical data was obtained from an actual nonylphenol production unit. The data contains information related to the equipment, process operating parameters, and stream composition data, including feed streams’ composition and flow rate. With this information, the flowsheet is built in the Aspen Plus® software. For all the different evaluated conditions, optimization is performed to minimize the dinonylphenol production. 3.1 Simulation developmentThe first step in building the simulation model involved obtaining actual stream data, specifically Column D-1 feed stream and Column D-2 distillate stream. Additionally, the operating parameters for both columns were investigated. A 3-year time interval for data gathering was established from March 2016 to March 2019. The historical data was supplied by the nonylphenol plant. From the data, the average and the standard deviation were calculated, in addition to assessing superior and inferior limits. Only steady-state operation data was considered, so plant startup and shutdown operation data were disregarded. Table 1 presents the maximum and minimum values for Column D-1 feed stream and Column D-2 distillate stream. | Component | D-1 feed stream | D-2 distillate stream |

|---|

| Nonylphenol, %p | 50–70 | 95–100 | | Dinonylphenol, %p | 0–5 | 0–3 | | Phenol, %p | 20–40 | 0–1 | | Nonene, %p | 0–15 | 0–1.5 | | Water, %p | 0–0.5 | 0–0.2 |

Specification limits for separation system sampling points. The ideal stream composition is defined to attain the case study objective. This is done by evaluating the periods when dinonylphenol was minimum. The plant production data is available in monthly intervals; thus 3 months were selected as the minimum dinonylphenol-production periods. 3.2 Thermodynamic modelThe definition of the selected thermodynamic model for the nonylphenol production system simulation is a crucial step for attaining accurate simulation results. The component’s thermodynamic, kinetic, and transport properties are evaluated using the adequate thermodynamic model [ 11 ]. In this manner, the component mixture thermodynamic relations and liquid-vapor equilibrium condition in the columns are precisely calculated, hence yielding accurate outgoing stream calculations. Considering that the compounds present in the process are majorly very polar, that no electrolytes are present, and that the operating pressure is lower than 10 bar, the NRTL model was selected. Besides being the appropriate model in the decision tree given by the simulator, previous studies performed by the plant also used the NRTL model, and the results from these previous studies were deemed accurate. 3.3 Distillation column operating data validationWith the selection of the NRTL thermodynamic model, simulations were performed with Aspen Plus® using the columns’ operating date from the unit process flow diagrams (PFD) and equipment data sheet. As these documents also contain the unit material balance for the design condition, this means that the simulation results can be compared with the material balance results. The packed columns are controlled by the bottom temperature as specified by design. Therefore, this variable was defined as a parameter that must be met by the simulation results. Another important validation point is compliance with the expected outgoing stream composition. In this manner, the nonylphenol in Column D-2 distillate stream must also be met by the simulation results. For the simulation validation, two situations were considered: comparative evaluation with design conditions and with actual operating conditions obtained from plant instrumentation. For the design scenario, Column D-2 feed and distillate stream compositions are obtained by using the unit material balance, the packed columns’ top and bottom temperatures, the reboilers’ heat loads, and the hot utility flow rate used in these reboilers. For the actual operating scenario, the distillate stream composition is compared with the stream analytical composition measurements, and also by the actual column top and bottom temperature, as well as the measured column temperature profile. 3.4 Operating conditions evaluationTwo operating strategies are feasible to achieve dinonylphenol reduction, which is the study optimization objective. The first strategy consists in reducing the dinonylphenol in the reaction stage. The second strategy is for Column D-2 to produce a distillate stream (nonylphenol product) with the maximum allowable dinonylphenol content. This strategy can be interpreted as contaminating the nonylphenol product to the limit established by market specifications. Using the 3-month low dinonylphenol yield, the average operating condition values were used as simulation input parameter values. In this manner, it is possible to compare the simulation results of the product outgoing streams for different flow rates. The results define the feed flow rate range that complies with the required production targets, and also the results show how dinonylphenol production varies according to the feed flow rate. The simulation results also show how the reboilers’ heat loads vary with the feed flow rate. Hence, the hot utility (Thermex) consumption and the resulting operating costs are also evaluated. 3.5 Stream average properties and compositionsTables 2 and 3 show the main values for the stream operating variables (input and output) for the nonylphenol purification stage. The input variables are used for the simulation model configuration, and the output variables are compared with the simulation results, so the results can be validated. | Description | Average Jan/2017 | Average Jun/2018 | Average Mar/2019 |

|---|

| Product outgoing flow rate (nonylphenol) (kg/h) | 1519 | 1279 | 1077 | | D-2 top pressure (bar abs) | 0.0733 | 0.0733 | 0.0725 | | D-2 head loss from bottom to top (bar) | 0.0046 | 0.0026 | — | | D-2 top temperature (°C) | 211 | 211 | 210 | | D-2 bottom temperature (°C) | 261 | 262 | 263 | | D-1 feed flow rate (kg/h) | 3535 | 3030 | 2713 | | D-1 top pressure (bar abs) | 0.333 | 0.333 | 0.333 | | D-1 head loss from bottom to top (bar) | 0.018 | 0.015 | 0.012 | | D-1 feed temperature (°C) | 158 | 152 | 155 | | D-1 top temperature (°C) | 135 | 132 | 136 | | D-1 bottom temperature (°C) | 254 | 256 | 257 |

Average operating parameter values. | Stream | Component | Average Jan/17 | Average Jun/18 | Average Mar/19 |

|---|

| D-1 feed | Nonylphenol, %p | 51.13 | 49.32 | 48.32 | | Dinonylphenol, %p | 1.50 | 1.64 | 1.76 | | Phenol, %p | 35.14 | 30.28 | 30.71 | | Nonene, %p | 12.22 | 18.76 | 19.21 | | D-2 distillate | Nonylphenol, %p | 98.01 | 97.55 | 97.20 | | Dinonylphenol, %p | 1.38 | 1.99 | 2.23 | | Phenol, %p | 0.27 | 0.40 | 0.52 | | Nonene, %p | 0.34 | 0.06 | 0.06 |

Average composition for D-1 feed stream and D-2 distillate stream (disregarding water content). The average composition shown in Table 3 for Column D-1 feed stream was used as simulation input variables. Column D-2 distillate stream composition values are compared with the simulation results. The latter stream average flow rate is calculated for the result comparison. The table shows the production results for the period between 2017 and 2019. Notably, the nonylphenol product stream flow rate shows a decline tendency, since nonylphenol demand has also decreased. For the 3-year period, the average nonylphenol product flow rate is 1195 kg/h ( Table 4 ). | Year | Nonylphenol production (t) | Average hourly production (kg/h) |

|---|

| 2017 | 9650 | 1469 | | 2018 | 7728 | 1176 | | 2019 | 6183 | 941 |

Nonylphenol average production. 2019 considers the production from January to March, and the projection for the remainder of the year. 3.6 Separation system validationTable 5 data were obtained from the plant project data. Reflux ratio and reboiler heat input data were obtained from the unit design specifications. | Input | D-1 | D-2 |

|---|

| Number of stages | 8 | 6 | | Condenser type | Total | Total | | Reboiler type | Kettle | Kettle | | Feed stage | 5 | 4 | | Column pressure | 0.240 bar abs | 0.0667 bar abs | | Hot utility | Thermex | Thermex | | Structured packing | Sulzer BX 50 | Sulzer BX 50 | | Reflux ratio | 0.1 | 0.1 | | Reboiler heat load | 343 Mcal/h | 146 Mcal/h |

Simulation input data for packed columns D-1 and D-2. Although the actual Column D-1 condenser is a partial one, the simulation considered a total condenser for simplification purposes. The reason for the use of a partial condenser in column D-1 is for the nonane removal, which was not an objective of the study. The used structured packing is Sulzer BX 50. The packing was inserted above and below the feed stage. The technical data used in the simulation was also obtained from the unit design data. For Column D-1, the upper part (rectification) packing has a 0.387 m diameter and encompasses Stages 2–4. This part of the column is 1.535 m in height and filled with packing. As for the lower part (stripping), the packing has 0.66 m diameter, and measures 1.345 m of height contemplating Stages 5–7. For Column D-2, the whole vessel has a 0.641 m de diameter. The rectification section is composed of Stages 2–3 and has a height of 0.68 m. The stripping section is composed of stages 4–5 and has a height of 1.195 m. Thermex is the name of the hot utility used in reboilers. The fluid is the Dowtherm™. A saturated vapor at 280°C, as the design specified. From the fluid data sheet, the latent heat, and the overall heat transfer coefficient were obtained. The Thermex fluid parameter values are given in Table 6 . | Parameter | Value |

|---|

| Latent heat of vaporization (kcal/kg) | 68.0 | | Incoming temperature (°C) | 280 | | Outgoing temperature (°C) | 280 | | Overall heat transfer coefficient (kcal/h.m .°C) | 1282 |

Thermex (hot utility) properties. According to design data, Thermex incoming and outgoing temperatures in the reboilers are equal, and this means that the Thermex vapor is saturated, and only latent is rejected from the hot utility. Table 7 lists the input data for Column D-1 feed stream in the process simulation for the simulation model evaluation. | Parameter | Value |

|---|

| Flow rate (kg/h) | 4059 | | Temperature (°C) | 156 | | Nonylphenol, %p | 52.551 | | Dinonylphenol, %p | 2.434 | | Phenol, %p | 39.838 | | Nonene, %p | 5.177 |

Feed stream input data according to design data. For the first simulation scenario, Column D-1 and D-2 bottom temperatures were set to 256°C and 277°C, respectively. The reboilers’ heat loads were varied so the required separation specification was met. Though the heat load values were kept close to the plant design value. The validation results are given in Table 8 . | Parameter | Design | Simulation | Variation |

|---|

| D-2 feed stream (kg/h) | 2231.8 | 2244.4 | 0.56% | | D-1 top temperature (°C) | 138 | 134 | −0.97% | | D-1 bottom temperature (°C) | 256 | 256 | 0.00% | | E-4 heat load (kcal/h) | 343,000 | 361,489 | 5.39% | | E-4 Thermex flow rate (kg/h) | 5170 | 5321 | 2.92% | | D-2 feed—nonylphenol, %p | 95.404 | 95.046 | −0.38% | | D-2 feed—dinonylphenol, %p | 4.427 | 4.402 | −0.56% | | D-2 feed—phenol, %p | 0.168 | 0.552 | 228.37% | | D-2 feed—nonene, %p | 0.001 | 0.000 | −74.54% | | D-2 distillate flow rate (kg/h) | 2164.5 | 2131.05 | −1.55% | | D-2 bottom flow rate (kg/h) | 67.2 | 113.35 | 68.67% | | D-2 top temperature (°C) | 215 | 209 | −1.22% | | D-2 bottom temperature (°C) | 277 | 277 | −0.05% | | E-5 heat load (kcal/h) | 146,000 | 158,418 | 8.51% | | E-5 Thermex flow rate (kg/h) | 2200 | 2332 | 5.99% | | D-2 distillate—nonylphenol, %p | 98.064 | 99.419 | 1.38% | | D-2 distillate—dinonylphenol, %p | 1.762 | 0.000 | −99.99% | | D-2 distillate—phenol, %p | 0.173 | 0.581 | 235.84% | | D-2 distillate—Nonene, %p | 0.001 | 0.000 | −73.19% |

Comparison between simulation results and design condition. temperature variations were calculated using the temperature values in Kelvin. Overall, the simulator was able to reproduce with good accuracy the actual conditions, although some discrepancies can be observed. Column D-1 bottom presented a very good correlation between simulated and actual data for both major components (nonylphenol and dinonylphenol). However, the simulation yielded a relatively higher phenol content at the bottom compared to the actual data. This occurs as the phenol quantity in the bottom stream is small in absolute numbers both in the simulated results and the actual date. Therefore, small deviations can result in high relative variation. As for Column D-1, both reboiler (E-4) heat load and Thermex flow rate present also low deviation values, 3% and 5% respectively. For Column D-2 distillate stream, only nonylphenol and nonene presented low relative variation values, and the reason is similar to the one described for Column D-1 bottom stream. An important difference is in the dinonylphenol subproduct stream (bottom), where the simulation yielded a value 68% higher than the actual value. This difference can lead to false optimal points. For the evaluated production months, Column D-1 feed stream properties are given in Table 9 . | Properties | Jan/17 | Jun/2018 | Mar/2019 |

|---|

| Flow rate (kg/h) | 3535 | 3030 | 2713 | | Temperature (°C) | 158.0 | 152.5 | 155.0 | | Nonylfenol, %p | 51.134 | 49.317 | 48.318 | | Dinonylphenol, %p | 1.502 | 1.641 | 1.762 | | Phenol, %p | 35.143 | 30.283 | 30.706 | | Nonene, %p | 12.220 | 18.759 | 19.214 |

Column D-1 feed stream properties. Table 10 shows the comparison between simulation results using the D-1 feed stream average flow rate and composition for 2019, and the evaluated 3-month data. | Property | Average

2019 | Jan/2017 | Jun/2018 | Mar/2019 |

|---|

| Column D-2 feed stream flow rate (kg/h) | 1438 | 1376 | 1332 | 1309 | | Column D-1 top temperature (°C) | 134 | 131 | 127 | 127 | | Column D-1 bottom temperature (°C) | 256 | 256 | 256 | 256 | | Reboiler E-4 heat load (kcal/h) | 231,536 | 219,220 | 217,084 | 214,487 | | Reboiler E-4 hot utility flow rate (kg/h) | 3571 | 3381 | 3348 | 3308 | | D-1 Bottom stream—nonylphenol, %p | 95.046 | 96.627 | 96.258 | 95.957 | | D-1 Bottom stream—dinonylphenol, %p | 4.402 | 2.835 | 3.201 | 3.499 | | D-1 Bottom stream—phenol, %p | 0.552 | 0.538 | 0.540 | 0.543 | | D-1 Bottom stream—nonene, %p | 0.000 | 0.001 | 0.001 | 0.001 | | D-2 Distillate stream flow rate (kg/h) | 1364 | 1331 | 1284 | 1257 | | D-2 Bottom stream flow rate (kg/h) | 73.82 | 44.71 | 48.62 | 52.37 | | Column D-2 top temperature (°C) | 209 | 212 | 212 | 212 | | Column D-2 bottom temperature (°C) | 277 | 277 | 278 | 278 | | Reboiler E-5 heat load (kcal/h) | 101,467 | 99,733 | 96,331 | 94,417 | | Reboiler E-5 hot utility flow rate (kg/h) | 1565 | 1538 | 1486 | 1456 | | D-2 distillate stream—nonylphenol, %p | 99.419 | 99.444 | 99.438 | 99.433 | | D-2 distillate stream—dinonylphenol, %p | 0.000 | 0.000 | 0.000 | 0.000 | | D-2 distillate stream—phenol, %p | 0.581 | 0.556 | 0.560 | 0.565 | | D-2 distillate stream—nonene, %p | 0.000 | 0.001 | 0.001 | 0.001 |

Comparison between simulation results and plant data. For both the simulation results and the evaluated 3 months, Reactor R-2 effluent stream has a low dinonylphenol content. Hence, D-2 bottom stream (dinonylphenol subproduct) flow rate is small compared to the D-2 distillate stream (nonylphenol product) flow rate. In comparison to Table 3 data, Table 10 shows a significantly lower dinonylphenol content in the D-2 distillate stream. A possible explanation for this difference is that the plant usually operates Column D-2 with a low reflux ratio to deliberately produce a high dinonylphenol content product stream but still in compliance with market demands. Column D-2 temperature profile is not altered significantly with the flow rate. This is expected as feed composition has a much greater effect on column temperature than feed flow rate. The results prove that as composition varies, temperature varies significantly. Another parameter that has a direct influence on column temperature is the column operating pressure. As the nonylphenol product becomes purer, the stream’s flow rate decreases. The lower dinonylphenol content in R-2 effluent makes the separation in Column D-2 easier and that can be noted in the lower reflux ratio. Hence, this reduces the plant’s operating cost. Since composition has a larger effect on column performance than feed flow rate, simulation results are obtained for different dinonylphenol to nonylphenol ratios (DNF). The DNF ratios for the 3 evaluated months are given in Table 11 . | Period | Jan/2017 | Jun/2018 | Mar/2019 |

|---|

| DNF ratio | 0.034 | 0.038 | 0.042 | | Variation from 2019 average | −36.18% | −28.02% | −20.83% |

DNF ratio variation for the 3 evaluated months. In January 2017, the largest DNF ratio variation occurred as the dinonylphenol content in D-2 feed stream reaches the lowest value. This means that for such composition, the D-1 distillate stream already meets market requirements, and this stream could even completely by-pass Column D-2. 3.7 Energy consumption analysisAs columns’ operating conditions are altered, an assessment of the reboilers’ heat loads is made. These heat loads have a direct influence on the hot utility heat load, and also on the financial expenditure to operate the reboilers. Table 12 shows the heat load values per nonylphenol produced. | Reboiler | 2019 average | Jan/2017 | Jun/2018 | Mar/2019 |

|---|

| E-4 (D-1) (kJ/kg NF) | 710.37 | 690.07 | 708.65 | 721.40 | | E-5 (D-2) (kJ/kg NF) | 316.01 | 313.94 | 314.46 | 314.19 | | Total (kJ/kg NF) | 1026.38 | 1004.01 | 1023.11 | 1035.59 | | Variation from 2019 average | | −2.18% | −0.32% | −0.90% |

Simulation results for reboiler heat loads. For Reboiler E-4, only in March 2019, the heat load surpassed the 2019 average values. For Reboiler E-5, the heat load is lower than the average 2019 value for all months. The same is repeated for the sum of both heat loads. Therefore, by repeating January 2017 conditions, a 2% energy reduction is attained. Thermex vapor is generated in a natural gas boiler. The following considerations are made: 100% efficiency in heat transfer from natural gas combustion to Thermex, the natural gas inferior calorific value of 33,500 kJ/m 3 , the natural gas density is 0.7902 kg/m 3 (IEA, 2019), and the natural gas cost is R$2.48/m 3 . Therefore, the heat load cost is 6.29.10 −5 R$/kJ. A financial assessment is made according to the mentioned values and Table 12 values. The results are given in Table 13 . | Jan/2017 | Jun/2018 | Mar/2019 |

|---|

| Difference (R$) | −827.27 | −120.98 | −340.63 |

Expenditure variation for the heat loads’ sum in the 3 evaluated months. Using the January 2017 value, the expenditure savings in a whole year could amount to R$ 9927.19. 3.8 Minimization of dinonylphenol productionBased on the months when dinonylphenol subproduct stream flow rate was minimal, the operating parameters of the nonylphenol production unit during these months are recommended as operating setpoints. As January 2017 presented the lowest dinonylphenol subproduct stream flow rate, the month’s parameters are given in Table 14 . | Parameter | Values |

|---|

| D-1 feed flow rate (kg/h) | 2600 | | Reactor conversion | 0.44 | | Nonene/raw phenol ratio | 1.36 | | Nonene/recycled phenol ratio | 0.588 | | D-1 reflux ratio | 0.1 | | D-2 reflux ratio | 0.1 | | D-1 operating pressure (bar abs) | 0.333 | | D-2 operating pressure (bar abs) | 0.0733 | | DNF/NF stream flow rate ratio | 0.0285 |

Recommended new operating setpoints. 3.9 Analysis of the operating pressure effectAs the purity of distillation column outgoing streams is defined according to process requirements, the distillation column design depends on the definition of two degrees of freedom: the column operating pressure and the reflux ratio (or the number of stages). Column operating pressure influences the equilibrium curve for the heavy and light key components, the column temperature, the condenser and reboiler heat loads, the condenser and reboiler exchange areas, the required utilities, the column diameter, and the column wall thickness, among other factors [ 12 ]. Therefore, defining the pressure is a crucial step in distillation column design. The greatest challenge in defining the column operating pressure is that there is no established methodology for doing so, instead a handful of heuristics are often used and that can lead to sub-optimal designs [ 13 ]. Thorough optimization studies can be performed to attain a more cost-efficient design [ 14 ] but such studies are not always feasible as many economical parameters can be at the maximum, estimated with a reasonable degree of certainty. Even if the parameters were known, optimizing a distillation column is a time-consuming effort, and depending on the software and hardware used, the obtained solution is likely to be a local optimal and not a global optimal. That does not mean that operating pressure optimization should not be pursued but it means that engineers prefer to use heuristics to quickly attain a solution regardless of whether it is an optimal one or a feasible one. In spite of optimization study difficulties, project and process engineers must comprehend the operating pressure effects on the distillation column operation. Firstly, relative volatility between light and heavy key components is usually inversely proportional to the operating pressure [ 15 ]. Hence, the lower the column operating pressure is, the higher the relative volatility is, and this means that at lower pressure, separation between key components can be made in fewer stages and with a lower reflux ratio. Evidently, how much pressure affects relative volatility depends on the components being separated. Using Column D-1 feed stream data from Table 7 , the minimum number of stages, minimum reflux ratio, and temperature profiles for Columns D-1 and D-2 are analyzed as a function of the column operating pressure. The results for pressure variation are given in Tables 15 and 16 . For Table 16 , the simulations are made for a D-1 operating pressure of 0.240 bar abs. | Operating pressure (bar) | Minimum number of stages | Minimum reflux ratio | Bottom temperature (°C) | Top temperature (°C) |

|---|

| 0.213 | 3.28 | 0.0129 | 257 | 114 | | 0.227 | 3.30 | 0.0134 | 259 | 116 | | 0.240 | 3.32 | 0.0138 | 261 | 118 | | 0.253 | 3.34 | 0.0142 | 263 | 119 | | 0.267 | 3.37 | 0.0146 | 265 | 121 | | 0.280 | 3.39 | 0.0150 | 266 | 122 | | 0.293 | 3.41 | 0.0154 | 268 | 124 |

Column D-1 operating pressure variation effect. | Operating pressure (bar) | Minimum number of stages | Minimum reflux ratio | Bottom temperature (°C) | Top temperature (°C) |

|---|

| 0.0600 | 3.08 | 0.0114 | 318 | 206 | | 0.0633 | 3.10 | 0.0117 | 320 | 207 | | 0.0667 | 3.11 | 0.0120 | 322 | 209 | | 0.0700 | 3.13 | 0.0123 | 324 | 210 | | 0.0733 | 3.14 | 0.0126 | 325 | 212 | | 0.0767 | 3.15 | 0.0128 | 327 | 213 | | 0.0800 | 3.17 | 0.0131 | 329 | 214 |

Column D-2 operating pressure variation effect. As nonylphenol and dinonylphenol have a considerable difference in molecular weight, and consequently in relative volatility, the results in Tables 15 and 16 show that pressure variation has a small effect on the minimum number of stages and minimum reflux ratio. This small effect is also due to the relatively narrow simulated pressure variation range. As for the columns’ bottom and top temperatures, despite the very low pressures, the temperatures are high. This is expected since dinonylphenol is a large molecule with a very high boiling point. As a suggestion for the plant’s future optimization efforts, operating Column D-1 with an even lower pressure could yield a bottom temperature where Thermex could be replaced with high-pressure steam. As for Column D-2, this is not possible, as this column already operates near full vacuum. 4. ConclusionsThe study aimed at subproduct (dinonylphenol) reduction and also heat load reduction. For these aims, a thorough investigation of the design conditions, and historical plant data was made to determine the months that yielded the lowest dinonylphenol production. The plant relies on two strategies to reduce the dinonylphenol production, and these are defining reactor conditions that minimize conversion of nonylphenol into dinonylphenol and increasing dinonylphenol content in the product (nonylphenol) stream to the maximum allowable composition. Aspen Plus® was the simulator used to investigate a new operating condition for the nonylphenol production unit to attain the study goals. The results indicate that a 36% subproduct reduction is possible. This value is achieved by a comparative analysis between simulation results and data from months where subproduct production reached minimum values. By simulating the nonylphenol plant design conditions, operating parameters are obtained for the reaction, phenol recovery, and nonylphenol purification stages. These recommended parameters are validated using historical plant data. The new simulated condition reduces the reboilers’ heat loads, and this can lead to a 2% reduction in hot utility consumption. - 1. Lorenc JF, Lambeth G, Scheffer W. Alkylphenols. In: Kirk-Othmer Encyclopedia of Chemical Technology. New York: John Wiley & Sons, Inc; 2003. DOI: 10.1002/0471238961.0112112512151805.a01.pub2

- 2. Arné M. Nonionic Surfactants. California: SRI International: Process Economics Program; 1984

- 3. Dow Chemical Company. Dowtherm™ A Heat Transfer Fluid: Product Technical Data. 2011. [Online]. Available from: https://www.appliedthermalfluids.com/wp-content/uploads/2018/02/Dowtherm-A-heat-transfer-fluid-MSDS.pdf

- 4. Olujić Ž. Chapter 1—Types of distillation column internals. In: Górak A, Olujić Ž, editors. Distillation Equipment and Processes. Cambridge, Massachusetts, USA: Academic Press; 2014. pp. 1-34. DOI: 10.1016/B978-0-12-386878-7.00001-2

- 5. McCabe WL, Smith JC, Harriot P. Unit Operations of Chemical Engineering. 7th ed. New York, NY, USA: McGraw Hill Chemical Engineering Series; 2007

- 6. Stewart MI. Condensate stabilization. Surface Production Operations (Gulf Professional Publishing). 2014; 2 :259-277. DOI: 10.1016/b978-0-12-382207-9.00006-8

- 7. Lange A, Fieg G. Designing novel structured packings by topology optimization and additive manufacturing. Computer Aided Chemical Engineering. 2022; 49 :1291-1296. DOI: 10.1016/B978-0-323-85159-6.50215-3

- 8. Dzhonova-Atanasova D, Stefanova K, Nakov S. On liquid flow maldistribution through investigation of random open-structure packings. Designs. 2023; 7 :47. DOI: 10.3390/designs7020047

- 9. Jerzy M. Prediction of separation efficiency of structured and stacked packings under low and normal pressure. Chemical Engineering Research and Design. 2022; 186 :713-729. DOI: 10.1016/j.cherd.2022.07.016

- 10. Sandler SI. Using Aspen Plus® in Thermodynamics Instruction. New Jersey: John Wiley & Sons, Inc; 2015

- 11. Al-Malah KIM. Aspen plus®: Chemical Engineering Applications. New Jersey: John Wiley & Sons Inc; 2017

- 12. Liu ZY, Jobson M. The effect of operating pressure on distillation column throughput. Computers and Chemical Engineering Supplement. 1999; 23 :S831-S834. DOI: 10.1016/S0098-1354(99)80204-X

- 13. Luyben WL. Distillation column pressure selection. Separation and Purification Technology. 2016; 168 :62-67. DOI: 10.1016/j.seppur.2016.05.015

- 14. Cui C, Liu S, Sun J. Optimal selection of operating pressure for distillation columns. Chemical Engineering Research and Design. 2018; 137 :291-307. DOI: 10.1016/j.cherd.2018.07.028

- 15. Wankat PC. Separation Process Engineering—Includes Mass Transfer Analysis. 3rd ed. New Jersey, NY, USA: Prentice-Hall; 2012

© The Author(s). Licensee IntechOpen. This chapter is distributed under the terms of the Creative Commons Attribution 3.0 License , which permits unrestricted use, distribution, and reproduction in any medium, provided the original work is properly cited. Continue reading from the same bookEdited by Raffaello Papadakis Published: 21 August 2024 By Ali Boubakri, Salah Al-Tahar Bouguecha and Amor Ha... 137 downloads By Jaime Alfonzo Irahola Ferreira 89 downloads By Parul Tomar and Deepali Jain 125 downloads IntechOpen Author/Editor? To get your discount, log in . Discounts available on purchase of multiple copies. View rates Local taxes (VAT) are calculated in later steps, if applicable. Support: [email protected]  |

![the case study of vanitas chapter 30 Ombra [Manhuas Rule Scans]](https://cdn.1stmangago.com/thumbs/2f868519e60ede45279678d21662627e2a89e4b0_1080_1511_249884.jpeg)

IMAGES

COMMENTS

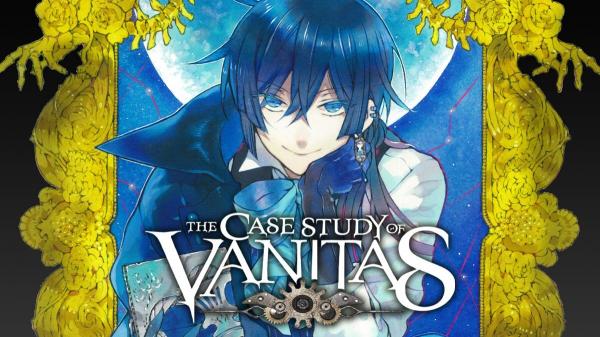

The Case Study of Vanitas (Japanese: ヴァニタスの手記カルテ, Hepburn: Vanitasu no Karute) is a Japanese manga series written and illustrated by Jun Mochizuki. It has been serialized in Square Enix's shōnen manga magazine Monthly Gangan Joker since December 2015. In North America, the manga is published in English by Yen Press.

There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas," a cursed grimoire that would one day take his vengeance on all vampires; this is how the story goes at least. Vanitas no Carte follows Noé, a young man travelling aboard an airship in 19th ...

Read The Case Study of Vanitas (Official) - Chapter 30 | MangaJinx. The next chapter, Chapter 31 is also available here. Come and enjoy! There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas,"; a cursed grimoire that would one day take his vengeance ...

There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas," a cursed grimoire that would one day take his vengeance on all vampires; this is how the story goes at least. Vanitas no Carte follows Noé, a young man travelling aboard an airship in 19th ...

The Case Study of Vanitas (Japanese: ヴァニタスの手記カルテ, Hepburn: Vanitasu no Karute) is a Japanese manga series written and illustrated by Jun Mochizuki. It has been serialized in Square Enix's shōnen manga magazine Monthly Gangan Joker since December 2015. In North America, the manga is published in English by Yen Press.

forfun 3K + 32.3K 932 days ago. There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas," a cursed grimoire that would one day take his vengeance on all vampires; this is how the story goes at least.

Vanitas No Carte - Chapter 3. Vanitas No Carte - Chapter 2. Vanitas No Carte - Chapter 1. Main Characters. Vanitas is one of the main protagonists of The Case Study Of Vanitas. He presents himself as an "average human being" using the power of the Book of Vanitas to cure vampires of the Blue Moon curse.

The Case Study of Vanitas Chapter 30 is manga/manhwa/manhua written by updating and updated daily and free on Manhuahot.to. Enjoy your favorite manhua with Manhuahot.to!

You are reading Vanitas no Carte manga chapter 30. Read Chapter 30 of Vanitas no Carte manga online. Search New Mangas Recent ... Visit Advanced Search Missing Manga Close. Vanitas no Carte Chapter 30. The Case Study of Vanitas Chapter 30. Ad. Toggle Page Numbers Chapter Selector. Previous Chapter Next Chapter. page 1/32. page 2/32. page 3/32 ...

The Case Study of Vanitas. Jun Mochizuki. Fantasy Action Media Tie-ins. Copy URL of this series (C)Jun Mochizuki/SQUARE ENIX ... Updated to the latest chapter on the app! Mémoire 1 -1. Free. Vanitas: In the Event of Rusty Hopes. Read for free. Mémoire 1 -2. ... Mémoire 30 -2. Strascinando: Tremolo. Exclusive on the app! Mémoire 30 -3 ...

Rumors revolving around The Book of Vanitas, a clockwork grimoire of dubious reputation, draw Noé, a young vampire in search of a friend's salvation, to Paris. What awaits him in the City of Flowers, however, is not long hours treading the pavement or rifling through dusty bookshops in search of the tome. Instead, his quarry comes to him...in the arms of a man claiming to be a vampire doctor ...

4.33 out of 5 from 939 votes. Rank #263. Rumors revolving around The Book of Vanitas, a clockwork grimoire of dubious reputation, draw Noé, a young vampire in search of a friend's salvation, to Paris. What awaits him in the City of Flowers, however, is not long hours treading the pavement or rifling through dusty bookshops in search of the tome.

Read the next chapter of The Case Study of Vanitas at the same time as Japan! ... 4.9 4.9 out of 5 stars 30 $1.99 Read the next chapter of The Case Study of Vanitas the same day as Japan! Read more. Buy now with 1-Click ® Sold by: Yen Press LLC The Case Study of Vanitas #49 ...

Volume 1 Chapter 1 : Vanitas: In the Event of Rusty Hopes. forfun 3K + 32.3K 931 days ago. There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas," a cursed grimoire that would one day take his ...

The Case Study of Vanitas is a manga written and illustrated by Jun Mochizuki.Set in 19th century Paris and contains vampire and steampunk thematics. The story focuses on the young Vanitas who possesses the grimoire called The Book of Vanitas and uses it to heal cursed vampires. The vampire Noé Archiviste joins Vanitas in his quest to save cursed vampires.

The Case Study of Vanitas (Official) - Chapter 30 : There once lived a vampire known as Vanitas, hated by his own kind for being born under a blue full moon, as most arise on the night of a crimson one. Afraid and alone, he created the "Book of Vanitas," a cursed grimoire that would one day take his vengeance on all vampires; this is how the story goes at least.

The Case Study of Vanitas10. Artist: Jun Mochizuki. Letterer: Bianca Pistillo. Translated by: Taylor Engel. Mikhail's machinations have succeeded in turning Noé and Vanitas against each other—and in a desperate attempt to stop Noé, Dominique throws herself offff the Ferris wheel!

The anime television series The Case Study of Vanitas is based in on the manga series of the same name written and illustrated by Jun Mochizuki.On March 28, 2021, it was announced at AnimeJapan that the series would be receiving an anime television series adaptation by Bones.It was directed by Tomoyuki Itamura, with scripts overseen by Deko Akao and character designs by Yoshiyuki Ito.

The Case Study of Vanitas (Japanese: ヴァニタスの 手記 ( カルテ ), Hepburn: Vanitasu no Karute) is a Japanese manga series written and illustrated by Jun Mochizuki.It has been serialized in Square Enix's shōnen manga magazine Monthly Gangan Joker since December 2015. In North America, the manga is published in English by Yen Press.. The Case Study of Vanitas is set in a ...

Scorned by others of his kind for being born under a blue moon, the vampire Vanitas grew afraid and desolate. According to legend, he created a cursed grimoire known as the "Book of Vanitas," and it is said he would one day use it to bring retribution upon all vampires of the crimson moon. In 19th century Paris, Noé Archiviste is searching for the fabled Book of Vanitas. Whilst traveling ...

Nonylphenol is a very important product for the chemical industry due to its widespread use as a base for several other chemical products. Among the major industrial sectors that use nonylphenol is the production of non-ionic surfactants, which are used from the home and personal care industry to the agrochemical industry. This study aims to define the optimal or quasi-optimal operating ...